-

MenuRetour

-

Tarifs Pro

Remise 35%

-

-

Ouverture comptePro et particuliers

-

-

-

Qui sommes nous

-

-

Qui sommes nousAu Comptoir Hydraulique

-

-

-

BLOG

-

-

BLOGAU COMPTOIR HYDRAULIQUE

-

-

-

COMPOSANTS HYDRAULIQUE

-

-

Vérins hydraulique ↓Double et simple effet ▼

-

-

-

Moteurs hydraulique ↓OMM,OMP,OMR,OMS,OMT,OMV ▼

-

-

-

SUPPORTS MOTEURS - ↓Supports moteur OMP - OMR - OMS ▼

-

-

-

Douilles profilées - ↓Tube claveté - Cannelés - Réducteurs ▼

-

-

-

Moteurs de direction ↓OSPB - OSPC ▼

-

-

-

Flexibles hydraulique ↓Equipés de raccords BSP ▼

-

-

-

Raccords hydraulique ↓BSP 60° - Droits, coudés, Tès, Croix▼

-

-

-

Accouplements ↓Elastique, Dentés, Douilles, étoiles ▼

-

-

-

Bobines Hydraulique ↓Bobines NG6 - NG10 - Connecteurs ▼

-

-

-

Coupleurs hydraulique ↓ISO A, ISO B, A visser, Face plane, VCR, BRH ▼

-

-

-

Contrôles des Mouvements ↓anti retour - equilibrage - séquence ▼

-

-

-

Regulateurs débitsDiviseurs, Régulateurs 2 et 3 voies

-

-

-

REGULATEURS PRESSIONS ↓Limiteurs NG6 - Regulateurs moteur ▼

-

-

-

Contre paliers hydraulique ↓Conique et cylindrique Groupe 1 et 2 ▼

-

-

-

Distributeurs hydraulique ↓Manuel, électrique, fendeuses, électro + levier ▼

-

-

-

Electrodistributeurs hydraulique ↓Electrodistributeurs - Embases - joints ▼

-

-

-

Embrayages hydraulique ↓Mécanique - Electrique ▼

-

-

-

Filtres hydraulique ↓Crépines, Spin On, Tête aspiration refoulement ▼

-

-

-

Joints hydraulique ↓De vérins, pompes, moteurs, electro ▼

-

-

-

Manometres hydraulique ↓Manometres Vertical ou horizontal▼

-

-

-

Mini centrale hydraulique ↓Simple et double effets ▼

-

-

-

Multiplicateurs hydraulique ↓Male - Femelle - Avec pompe - Supports ▼

-

-

-

Pressostats hydraulique ↓FOX K4 - K5 - F3 ▼

-

-

-

MOTOPOMPES ↓Motopompes a la demande ▼

-

-

-

Pompes a Engrenages ↓Pompe a Engrenages GR0 - GR1 - GR2 - GR3 ▼

-

-

-

Pompes AgricolePompes Agricole - Bobard - Case - Manitou Etc

-

-

-

Pompes double hydraulique ↓Pompe Doubles - G1 - GR2 ▼

-

-

-

Pompes manuelle ↓Pompe a mains ▼

-

-

-

Refroidisseurs echangeur ↓Refroidisseurs échangeur chaleur 12 24 VDC ▼

-

-

-

Réservoirs hydraulique pour ↓Pompes a main - Mini centrale - Poids lourd ▼

-

-

-

Sécurités hydraulique ↓Prises Pression - Thermostats ▼

-

-

-

Vannes robinets ↓Vannes 2 ou 3 voies - Sélecteurs ▼

-

-

-

Sélecteurs hydraulique ↓3 Voies - 6 Voies Empilable - 8 Voies Cetop ▼

-

-

-

TélécommandesTélécommandes - Radiocommandes

-

-

-

Sommaire

-

-

A

-

-

-

-

B

-

-

-

C

-

-

-

D

-

-

Distributeur hydraulique

- Distributeur a leviers

- Tiroir - crantage

- Distributeur electrique

- Distributeur NG6 a leviers

- Distributeur pour fendeuse

- Electro NG6 + levier manuel

- Sélecteurs manuel

- Sélecteur électrique de circuits

-

Distributeur hydraulique

-

-

-

E

-

- Embases NG06

-

-

-

F

-

-

-

H

-

-

-

J

-

-

-

L

-

-

-

M

-

-

Moteurs hydraulique

- Moteurs hydrauliques Orbitaux

- Douille profilée - canelée

- Joints de moteurs orbitaux

- Moteurs de direction

- Support de fixation moteur

- Régulateurs débit moteur

- Régulateurs pression moteur

-

Moteurs hydraulique

-

-

-

-

P

-

-

-

-

R

-

-

-

S

-

-

-

-

T

-

-

-

V

-

-

-

-

-

GLOSSAIRE

-

-

Distributeur

-

-

Distributeurs a leviers

-

-

-

Tiroirs et crantages

-

-

-

Distributeurs NG6 avec levier

-

-

-

Distributeurs de fendeuses

-

-

-

Distributeurs NG6 a levier

-

-

-

Distributeurs electrique YE45

-

-

-

Selecteurs electrique

-

-

-

Electro

-

-

Electrodistributeurs NG6

-

-

-

Embases pour electro NG6

-

-

Valves intermediares NG6

-

-

Joints pour electro NG6

-

-

-

Bobines pour electro NG6

-

-

-

Connecteurs pour bobines

-

-

-

Electrodistributeurs NG10

-

-

-

Embases pour electro NG10

-

-

-

Valves intermediares NG6

-

-

Joints pour electro NG10

-

-

-

Bobines pour electro NG10

-

-

-

Selecteurs electrique

-

-

MenuRetour

-

Tarifs Pro

Remise 35%

-

-

Ouverture comptePro et particuliers

-

-

-

Qui sommes nous

-

-

Qui sommes nousAu Comptoir Hydraulique

-

-

-

BLOG

-

-

BLOGAU COMPTOIR HYDRAULIQUE

-

-

-

COMPOSANTS HYDRAULIQUE

-

-

Vérins hydraulique ↓Double et simple effet ▼

-

-

-

Moteurs hydraulique ↓OMM,OMP,OMR,OMS,OMT,OMV ▼

-

-

-

SUPPORTS MOTEURS - ↓Supports moteur OMP - OMR - OMS ▼

-

-

-

Douilles profilées - ↓Tube claveté - Cannelés - Réducteurs ▼

-

-

-

Moteurs de direction ↓OSPB - OSPC ▼

-

-

-

Flexibles hydraulique ↓Equipés de raccords BSP ▼

-

-

-

Raccords hydraulique ↓BSP 60° - Droits, coudés, Tès, Croix▼

-

-

-

Accouplements ↓Elastique, Dentés, Douilles, étoiles ▼

-

-

-

Bobines Hydraulique ↓Bobines NG6 - NG10 - Connecteurs ▼

-

-

-

Coupleurs hydraulique ↓ISO A, ISO B, A visser, Face plane, VCR, BRH ▼

-

-

-

Contrôles des Mouvements ↓anti retour - equilibrage - séquence ▼

-

-

-

Regulateurs débitsDiviseurs, Régulateurs 2 et 3 voies

-

-

-

REGULATEURS PRESSIONS ↓Limiteurs NG6 - Regulateurs moteur ▼

-

-

-

Contre paliers hydraulique ↓Conique et cylindrique Groupe 1 et 2 ▼

-

-

-

Distributeurs hydraulique ↓Manuel, électrique, fendeuses, électro + levier ▼

-

-

-

Electrodistributeurs hydraulique ↓Electrodistributeurs - Embases - joints ▼

-

-

-

Embrayages hydraulique ↓Mécanique - Electrique ▼

-

-

-

Filtres hydraulique ↓Crépines, Spin On, Tête aspiration refoulement ▼

-

-

-

Joints hydraulique ↓De vérins, pompes, moteurs, electro ▼

-

-

-

Manometres hydraulique ↓Manometres Vertical ou horizontal▼

-

-

-

Mini centrale hydraulique ↓Simple et double effets ▼

-

-

-

Multiplicateurs hydraulique ↓Male - Femelle - Avec pompe - Supports ▼

-

-

-

Pressostats hydraulique ↓FOX K4 - K5 - F3 ▼

-

-

-

MOTOPOMPES ↓Motopompes a la demande ▼

-

-

-

Pompes a Engrenages ↓Pompe a Engrenages GR0 - GR1 - GR2 - GR3 ▼

-

-

-

Pompes AgricolePompes Agricole - Bobard - Case - Manitou Etc

-

-

-

Pompes double hydraulique ↓Pompe Doubles - G1 - GR2 ▼

-

-

-

Pompes manuelle ↓Pompe a mains ▼

-

-

-

Refroidisseurs echangeur ↓Refroidisseurs échangeur chaleur 12 24 VDC ▼

-

-

-

Réservoirs hydraulique pour ↓Pompes a main - Mini centrale - Poids lourd ▼

-

-

-

Sécurités hydraulique ↓Prises Pression - Thermostats ▼

-

-

-

Vannes robinets ↓Vannes 2 ou 3 voies - Sélecteurs ▼

-

-

-

Sélecteurs hydraulique ↓3 Voies - 6 Voies Empilable - 8 Voies Cetop ▼

-

-

-

TélécommandesTélécommandes - Radiocommandes

-

-

-

Sommaire

-

-

A

-

-

-

-

B

-

-

-

C

-

-

-

D

-

-

Distributeur hydraulique

- Distributeur a leviers

- Tiroir - crantage

- Distributeur electrique

- Distributeur NG6 a leviers

- Distributeur pour fendeuse

- Electro NG6 + levier manuel

- Sélecteurs manuel

- Sélecteur électrique de circuits

-

Distributeur hydraulique

-

-

-

E

-

- Embases NG06

-

-

-

F

-

-

-

H

-

-

-

J

-

-

-

L

-

-

-

M

-

-

Moteurs hydraulique

- Moteurs hydrauliques Orbitaux

- Douille profilée - canelée

- Joints de moteurs orbitaux

- Moteurs de direction

- Support de fixation moteur

- Régulateurs débit moteur

- Régulateurs pression moteur

-

Moteurs hydraulique

-

-

-

-

P

-

-

-

-

R

-

-

-

S

-

-

-

-

T

-

-

-

V

-

-

-

-

-

GLOSSAIRE

-

-

Distributeur

-

-

Distributeurs a leviers

-

-

-

Tiroirs et crantages

-

-

-

Distributeurs NG6 avec levier

-

-

-

Distributeurs de fendeuses

-

-

-

Distributeurs NG6 a levier

-

-

-

Distributeurs electrique YE45

-

-

-

Selecteurs electrique

-

-

-

Electro

-

-

Electrodistributeurs NG6

-

-

-

Embases pour electro NG6

-

-

Valves intermediares NG6

-

-

Joints pour electro NG6

-

-

-

Bobines pour electro NG6

-

-

-

Connecteurs pour bobines

-

-

-

Electrodistributeurs NG10

-

-

-

Embases pour electro NG10

-

-

-

Valves intermediares NG6

-

-

Joints pour electro NG10

-

-

-

Bobines pour electro NG10

-

-

-

Selecteurs electrique

-

Qu'est ce que la pression ?

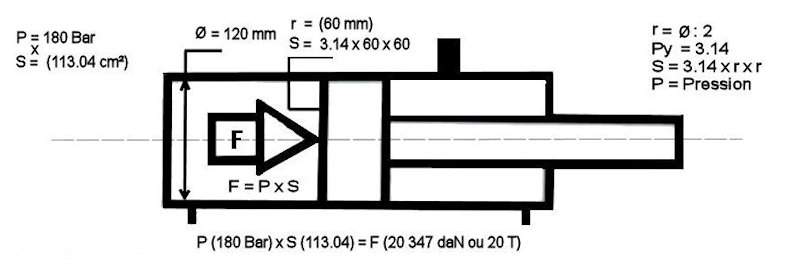

La pression est une FORCE qui s'exerce sur une surface et se mesure en bar. Donc P=F/S

Dans un système, la pression est une force physique qui se traduit par un échange de quantité de mouvement dans un système thermodynamique, notamment au sein d’un élément solide ou d’un fluide. Mais de quelle force s’agit-il exactement ? Quel est son rôle ? Et plus largement, qu’est-ce que la pression ? C’est ce que nous allons découvrir ensemble au fil de cet article, qui s’intéressera plus particulièrement au cas de la pression dans un circuit hydraulique.

Pour le décrire simplement, la pression est en fait l’intensité de la force qu’exerce, dans notre cas, un fluide, par unité de surface. Cette intensité s’exprime en pascals (Pa). Il est important de distinguer ici les notions de force et de pression, qui sont souvent sujets à confusion.

- La force : il s’agit d’un phénomène qui s’exerce sur un corps et peut le mettre en mouvement ou le déformer. Par exemple en le poussant, en le soulevant, en le tirant, etc. L’intensité de ce que l’on nomme la force s’exprime en Newton.

- La pression : la différence est ici très subtile et réside dans la surface sur laquelle s’exerce la force. La pression, comme déjà mentionné plus, s’exprime quant à elle en pascals (Pa), et correspond à la force divisée par la surface sur laquelle elle s’exerce. Par exemple, une pression d’un Pascal est une force d’un Newton exercée sur un mètre carré.

La pression dans un circuit hydraulique

Dans cet article nous nous penchons plus particulièrement sur la notion de pression dans un système hydraulique. La force des systèmes hydrauliques est basée sur une différence de pression entre deux zones. Cette différence provoque une section de l'équipement et génère un mouvement. En d'autres mots, c'est l'utilisation des fluides sous pression et des lois des liquides qui va générer un travail mécanique. La pression joue donc un rôle essentiel. Si elle est indispensable au bon fonctionnement du circuit hydraulique, il est aisément concevable que ce phénomène, qui génère la puissance, doit être contrôlé d'autant plus que les autres composants et toutes les parties du système hydraulique sont sous l'effet de la pression. En effet, une pression mal calibrée peut être à l’origine de disfonctionnements, et même, sur le long terme, peut endommager le circuit et les différents éléments qui le composent.

Comment réguler la pression ?

Il est donc essentiel de surveiller régulièrement la pression afin d’éviter les incidents, mais aussi pour ne pas trop malmener le matériel. Pour ce faire, on utilise un instrument appelé manomètre, qui permet de mesurer la pression dans le circuit. Ainsi, lorsque l’on constate que la pression est trop basse ou trop élevée, on peut intervenir pour la réguler. C’est aussi le rôle du limiteur de pression, qui permet de limiter la pression au sein du circuit. Il va dériver l’excès de pression vers le circuit basse tension.

La pression est donc indispensable pour le bon fonctionnement d’un circuit hydraulique. Il n’en demeure pas moins essentiel de la mesurer et le réguler le mieux possible. En effet, une pression mal régulée peut s’avérer problématique, et endommager le circuit sur le long terme. Les dispositifs permettant une surveillance et une vigilance constantes sont donc vivement recommandés.