-

MenuRetour

-

Tarifs Pro

Remise 35%

-

-

Ouverture comptePro et particuliers

-

-

-

Qui sommes nous

-

-

Qui sommes nousAu Comptoir Hydraulique

-

-

-

COMPOSANTS HYDRAULIQUE

-

-

Vérins hydraulique ↓Double et simple effet ▼

-

-

-

Moteurs hydraulique ↓OMM,OMP,OMR,OMS,OMT,OMV ▼

-

-

-

SUPPORTS MOTEURS - ↓Supports moteur OMP - OMR - OMS ▼

-

-

-

Douilles profilées - ↓Tube claveté - Cannelés - Réducteurs ▼

-

-

-

Moteurs de direction ↓OSPB - OSPC ▼

-

-

-

Flexibles hydraulique ↓Equipés de raccords BSP ▼

-

-

-

Raccords hydraulique ↓BSP 60° - Droits, coudés, Tès, Croix▼

-

-

-

Accouplements ↓Elastique, Dentés, Douilles, étoiles ▼

-

-

-

Bobines Hydraulique ↓Bobines NG6 - NG10 - Connecteurs ▼

-

-

-

Coupleurs hydraulique ↓ISO A, ISO B, A visser, Face plane, VCR, BRH ▼

-

-

-

Contrôles des Mouvements ↓anti retour - equilibrage - séquence ▼

-

-

-

Regulateurs débitsDiviseurs, Régulateurs 2 et 3 voies

-

-

-

REGULATEURS PRESSIONS ↓Limiteurs NG6 - Regulateurs moteur ▼

-

-

-

Contre paliers hydraulique ↓Conique et cylindrique Groupe 1 et 2 ▼

-

-

-

Distributeurs hydraulique ↓Manuel, électrique, fendeuses, électro + levier ▼

-

-

-

Electrodistributeurs hydraulique ↓Electrodistributeurs - Embases - joints ▼

-

-

-

Embrayages hydraulique ↓Mécanique - Electrique ▼

-

-

-

Filtres hydraulique ↓Crépines, Spin On, Tête aspiration refoulement ▼

-

-

-

Joints hydraulique ↓De vérins, pompes, moteurs, electro ▼

-

-

-

Manometres hydraulique ↓Manometres Vertical ou horizontal▼

-

-

-

Mini centrale hydraulique ↓Simple et double effets ▼

-

-

-

Multiplicateurs hydraulique ↓Male - Femelle - Avec pompe - Supports ▼

-

-

-

Pressostats hydraulique ↓FOX K4 - K5 - F3 ▼

-

-

-

MOTOPOMPES ↓Motopompes a la demande ▼

-

-

-

Pompes a Engrenages ↓Pompe a Engrenages GR0 - GR1 - GR2 - GR3 ▼

-

-

-

Pompes AgricolePompes Agricole - Bobard - Case - Manitou Etc

-

-

-

Pompes double hydraulique ↓Pompe Doubles - G1 - GR2 ▼

-

-

-

Pompes manuelle ↓Pompe a mains ▼

-

-

-

Refroidisseurs echangeur ↓Refroidisseurs échangeur chaleur 12 24 VDC ▼

-

-

-

Réservoirs hydraulique pour ↓Pompes a main - Mini centrale - Poids lourd ▼

-

-

-

Sécurités hydraulique ↓Prises Pression - Thermostats ▼

-

-

-

Vannes robinets ↓Vannes 2 ou 3 voies - Sélecteurs ▼

-

-

-

Sélecteurs hydraulique ↓3 Voies - 6 Voies Empilable - 8 Voies Cetop ▼

-

-

-

TélécommandesTélécommandes - Radiocommandes

-

-

-

Sommaire

-

-

A

-

-

-

-

B

-

-

-

C

-

-

-

D

-

-

Distributeur hydraulique

- Distributeur a leviers

- Tiroir - crantage

- Distributeur electrique

- Distributeur NG6 a leviers

- Distributeur pour fendeuse

- Electro NG6 + levier manuel

- Sélecteurs manuel

- Sélecteur électrique de circuits

-

Distributeur hydraulique

-

-

-

E

-

- Embases NG06

-

-

-

F

-

-

-

H

-

-

-

J

-

-

-

L

-

-

-

M

-

-

Moteurs hydraulique

- Moteurs hydrauliques Orbitaux

- Douille profilée - canelée

- Joints de moteurs orbitaux

- Moteurs de direction

- Support de fixation moteur

- Régulateurs débit moteur

- Régulateurs pression moteur

-

Moteurs hydraulique

-

-

-

-

P

-

-

-

-

R

-

-

-

S

-

-

-

-

T

-

-

-

V

-

-

-

-

GLOSSAIRE

-

-

Distributeur

-

-

Distributeurs a leviers

-

-

-

Tiroirs et crantages

-

-

-

Distributeurs NG6 avec levier

-

-

-

Distributeurs de fendeuses

-

-

-

Distributeurs NG6 a levier

-

-

-

Distributeurs electrique YE45

-

-

-

Selecteurs electrique

-

-

-

Electro

-

-

Electrodistributeurs NG6

-

-

-

Embases pour electro NG6

-

-

Valves intermediares NG6

-

-

Joints pour electro NG6

-

-

-

Bobines pour electro NG6

-

-

-

Connecteurs pour bobines

-

-

-

Electrodistributeurs NG10

-

-

-

Embases pour electro NG10

-

-

-

Valves intermediares NG6

-

-

Joints pour electro NG10

-

-

-

Bobines pour electro NG10

-

-

-

Selecteurs electrique

-

-

MenuRetour

-

Tarifs Pro

Remise 35%

-

-

Ouverture comptePro et particuliers

-

-

-

Qui sommes nous

-

-

Qui sommes nousAu Comptoir Hydraulique

-

-

-

COMPOSANTS HYDRAULIQUE

-

-

Vérins hydraulique ↓Double et simple effet ▼

-

-

-

Moteurs hydraulique ↓OMM,OMP,OMR,OMS,OMT,OMV ▼

-

-

-

SUPPORTS MOTEURS - ↓Supports moteur OMP - OMR - OMS ▼

-

-

-

Douilles profilées - ↓Tube claveté - Cannelés - Réducteurs ▼

-

-

-

Moteurs de direction ↓OSPB - OSPC ▼

-

-

-

Flexibles hydraulique ↓Equipés de raccords BSP ▼

-

-

-

Raccords hydraulique ↓BSP 60° - Droits, coudés, Tès, Croix▼

-

-

-

Accouplements ↓Elastique, Dentés, Douilles, étoiles ▼

-

-

-

Bobines Hydraulique ↓Bobines NG6 - NG10 - Connecteurs ▼

-

-

-

Coupleurs hydraulique ↓ISO A, ISO B, A visser, Face plane, VCR, BRH ▼

-

-

-

Contrôles des Mouvements ↓anti retour - equilibrage - séquence ▼

-

-

-

Regulateurs débitsDiviseurs, Régulateurs 2 et 3 voies

-

-

-

REGULATEURS PRESSIONS ↓Limiteurs NG6 - Regulateurs moteur ▼

-

-

-

Contre paliers hydraulique ↓Conique et cylindrique Groupe 1 et 2 ▼

-

-

-

Distributeurs hydraulique ↓Manuel, électrique, fendeuses, électro + levier ▼

-

-

-

Electrodistributeurs hydraulique ↓Electrodistributeurs - Embases - joints ▼

-

-

-

Embrayages hydraulique ↓Mécanique - Electrique ▼

-

-

-

Filtres hydraulique ↓Crépines, Spin On, Tête aspiration refoulement ▼

-

-

-

Joints hydraulique ↓De vérins, pompes, moteurs, electro ▼

-

-

-

Manometres hydraulique ↓Manometres Vertical ou horizontal▼

-

-

-

Mini centrale hydraulique ↓Simple et double effets ▼

-

-

-

Multiplicateurs hydraulique ↓Male - Femelle - Avec pompe - Supports ▼

-

-

-

Pressostats hydraulique ↓FOX K4 - K5 - F3 ▼

-

-

-

MOTOPOMPES ↓Motopompes a la demande ▼

-

-

-

Pompes a Engrenages ↓Pompe a Engrenages GR0 - GR1 - GR2 - GR3 ▼

-

-

-

Pompes AgricolePompes Agricole - Bobard - Case - Manitou Etc

-

-

-

Pompes double hydraulique ↓Pompe Doubles - G1 - GR2 ▼

-

-

-

Pompes manuelle ↓Pompe a mains ▼

-

-

-

Refroidisseurs echangeur ↓Refroidisseurs échangeur chaleur 12 24 VDC ▼

-

-

-

Réservoirs hydraulique pour ↓Pompes a main - Mini centrale - Poids lourd ▼

-

-

-

Sécurités hydraulique ↓Prises Pression - Thermostats ▼

-

-

-

Vannes robinets ↓Vannes 2 ou 3 voies - Sélecteurs ▼

-

-

-

Sélecteurs hydraulique ↓3 Voies - 6 Voies Empilable - 8 Voies Cetop ▼

-

-

-

TélécommandesTélécommandes - Radiocommandes

-

-

-

Sommaire

-

-

A

-

-

-

-

B

-

-

-

C

-

-

-

D

-

-

Distributeur hydraulique

- Distributeur a leviers

- Tiroir - crantage

- Distributeur electrique

- Distributeur NG6 a leviers

- Distributeur pour fendeuse

- Electro NG6 + levier manuel

- Sélecteurs manuel

- Sélecteur électrique de circuits

-

Distributeur hydraulique

-

-

-

E

-

- Embases NG06

-

-

-

F

-

-

-

H

-

-

-

J

-

-

-

L

-

-

-

M

-

-

Moteurs hydraulique

- Moteurs hydrauliques Orbitaux

- Douille profilée - canelée

- Joints de moteurs orbitaux

- Moteurs de direction

- Support de fixation moteur

- Régulateurs débit moteur

- Régulateurs pression moteur

-

Moteurs hydraulique

-

-

-

-

P

-

-

-

-

R

-

-

-

S

-

-

-

-

T

-

-

-

V

-

-

-

-

GLOSSAIRE

-

-

Distributeur

-

-

Distributeurs a leviers

-

-

-

Tiroirs et crantages

-

-

-

Distributeurs NG6 avec levier

-

-

-

Distributeurs de fendeuses

-

-

-

Distributeurs NG6 a levier

-

-

-

Distributeurs electrique YE45

-

-

-

Selecteurs electrique

-

-

-

Electro

-

-

Electrodistributeurs NG6

-

-

-

Embases pour electro NG6

-

-

Valves intermediares NG6

-

-

Joints pour electro NG6

-

-

-

Bobines pour electro NG6

-

-

-

Connecteurs pour bobines

-

-

-

Electrodistributeurs NG10

-

-

-

Embases pour electro NG10

-

-

-

Valves intermediares NG6

-

-

Joints pour electro NG10

-

-

-

Bobines pour electro NG10

-

-

-

Selecteurs electrique

-

Pompe Load Sensing : fonctionnement et utilisation

Amoureux de pompes hydrauliques en tout genre ou futurs professionnels, il peut être utile de démêler le bon grain de l'ivraie en matière de pompe hydraulique. Comment marchent les pompes load sensing, et les pompes hydrauliques en général ? Comme s'insèrent-elles dans nos moteurs ? C'est par ici que ça se passe!

Avant de passer au cœur de notre sujet, retour sur les moteur hydraulique .

Un moteur hydraulique a pour fonction de générer de l'énergie mécanique en utilisant la puissance hydraulique. C'est la transformation de l'hydraulique en mécanique qui créé la condition de son fonctionnement.

L'action de générer de la puissance de cette manière a recours à la pression des fluides. Pour cela, le moteur ne travaille, pour ainsi dire, pas seul. C'est la mise en combinaison des pompes, soupapes et autres réservoirs qui permettent de mettre ces fluides sous pression. Ces fluides sont ensuite canalisés en direction du moteur pour y produire de l'énergie mécanique et ainsi, assurer son fonctionnement.

Le dégagement de cette énergie permet le déploiement d'une grande force, ce qui explique qu'on ai recours à ces moteurs dans des cadres industriels ou alors agricoles, par exemple.

Maintenant, passons au rôle des pompes dans notre couple moteur hydraulique / pompes hydrauliques. Quelle est leur place ?

Les pompes hydrauliques

La pompe hydraulique est garante conjointe avec le moteur du fonctionnement de notre installation hydraulique. Mais comment marche-t-elle?

L'intérêt ainsi que le rôle d'une pompe hydraulique commence quand elle est liée à un moteur de même nature.

La pompe est mise sous tension quand le moteur s'active, et démarre ainsi l'action forçant le fluide hydraulique à entrer dans la pompe, puis à en sortir.

Les pièces de la pompe hydraulique maintiennent généralement le liquide dans la bonne direction, l'ensemble du processus pouvant s'inverser. Cette inversion de l'action et du sens du liquide sont propres au système hydraulique dans son ensemble, donc au moteur comme à la pompe.

La pompe hydraulique, quelle que soit son type et sa fonction, compte plusieurs composants essentiels garantissant son fonctionnement :

- Pistons

- Lobes

- Palettes

- Engrenages

On voit donc que la pompe hydraulique ne génère pas de force par elle-même, mais par le déplacement du fluide vers l'entrée et la sortie.

Plusieurs modèles existent, dont notre fameuse pompe Load Sensing. Penchons-nous enfin sur elle!

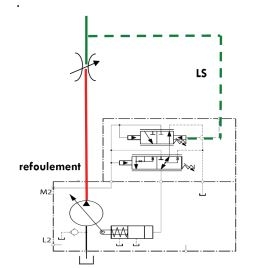

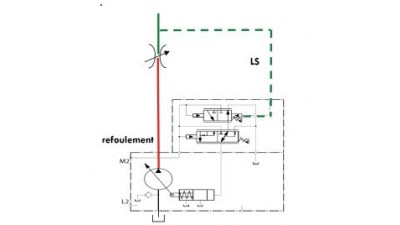

La pompe Load Sensing

Après cette longue introduction, mettons nous plus particulièrement sur le traitement de la pompe Load Sensing.

A la différence d'autres pompes, celle-ci s'ajuste automatiquement en cylindrée et pression, ce qui permet d'obtenir une distribution constante.

L'ajustement automatique fera que l'entrée et la sortie du distributeur à section variable et les récepteurs sera donc parfaitement calibrée d'entrée de jeu et permettra une réponse immédiate à la demande.

Par ailleurs, le fait que le calibrage soit d'ores et déjà impeccable permet une non rupture de la distribution et donc une alimentation constante et stable de notre installation.

Les pressions seront en effet toujours stables et la distribution, de fait, garantie.

A noter que la distribution est également sécurisée par une fonction d'annulation permettant une pression maximale et donc l'interruption immédiate en cas de besoin sur la canalisation de sortie. Et, de fait, l'arrêt du processus.

Cette adéquation permanente permet en outre une grande économie d'énergie, puisque le moteur n'a pas à forcer davantage pour fournir notre installation. La stabilité est ici un gain de puissance et également d'énergie, c'est donc un combo gagnant.

Vous connaissez dès à présent, non seulement le fonctionnement global d'une pompe hydraulique, mais également le cas plus particulier d'une pompe Load Sensing. A bientôt pour de nouvelles découvertes hydrauliques!